Engine

H5 1500cc SP

The engine came out of a 1970 VW Convertible that I picked up awhile back. It was rebuilt at some point to .40 over and is a good running engine. The cylinders don’t look to be oversized, but I would guess that they were increase to the 85.5mm during the rebuild, making this a 1600cc engine. It was taken down to the long block, everything was cleaned, blasted, and painted.

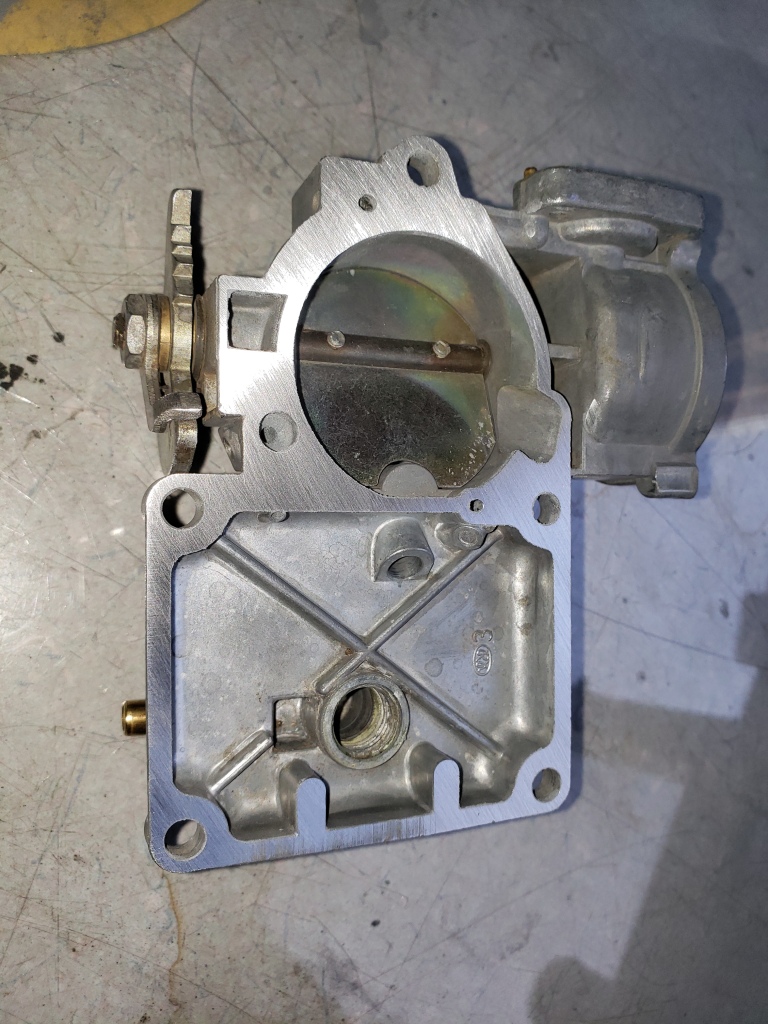

The tin was blasted, oil cooler welded (the mounting tab had a crack), mating surfaces filed, carburetor rebuilt, and surfaces sanded.

On a cart and almost ready for the car. All new Bosch cap, rotor, points, and wires. New exhaust and v-belt. I had this ready to go in a 6-volt vehicle before it was installed in this car. I changed the 6-volt coil to a 12-volt Bosch Blue, added a rebuilt 12-volt generator, restored the original air cleaner, and installed a new fuel pump from this picture.

| H5 | 1968 Aug. (1969) | 1500cc Dual relief, single port, 44bhp, DIN 1500 M157 |

Transmission

1966 Aug 15

# 9445023

The transmission was pulled out, but I kept the 1968 axles and tubes for the 1967 transmission that was going into the car. I was told that the reverse synchronizer was out and it will be set on the shelf as a core for a future build.

The 1967 unit that is going in was said to be rebuilt, pulled from the car for another project, and found on Craigslist. The gears and paddles all looked good on inspection and the only issue found was with the throw-out shaft and return spring. There was some damage from when the return spring broke, and both were replaced with the originals from the car. The thing shifts like a dream and there is no doubt work that has been done in the past.

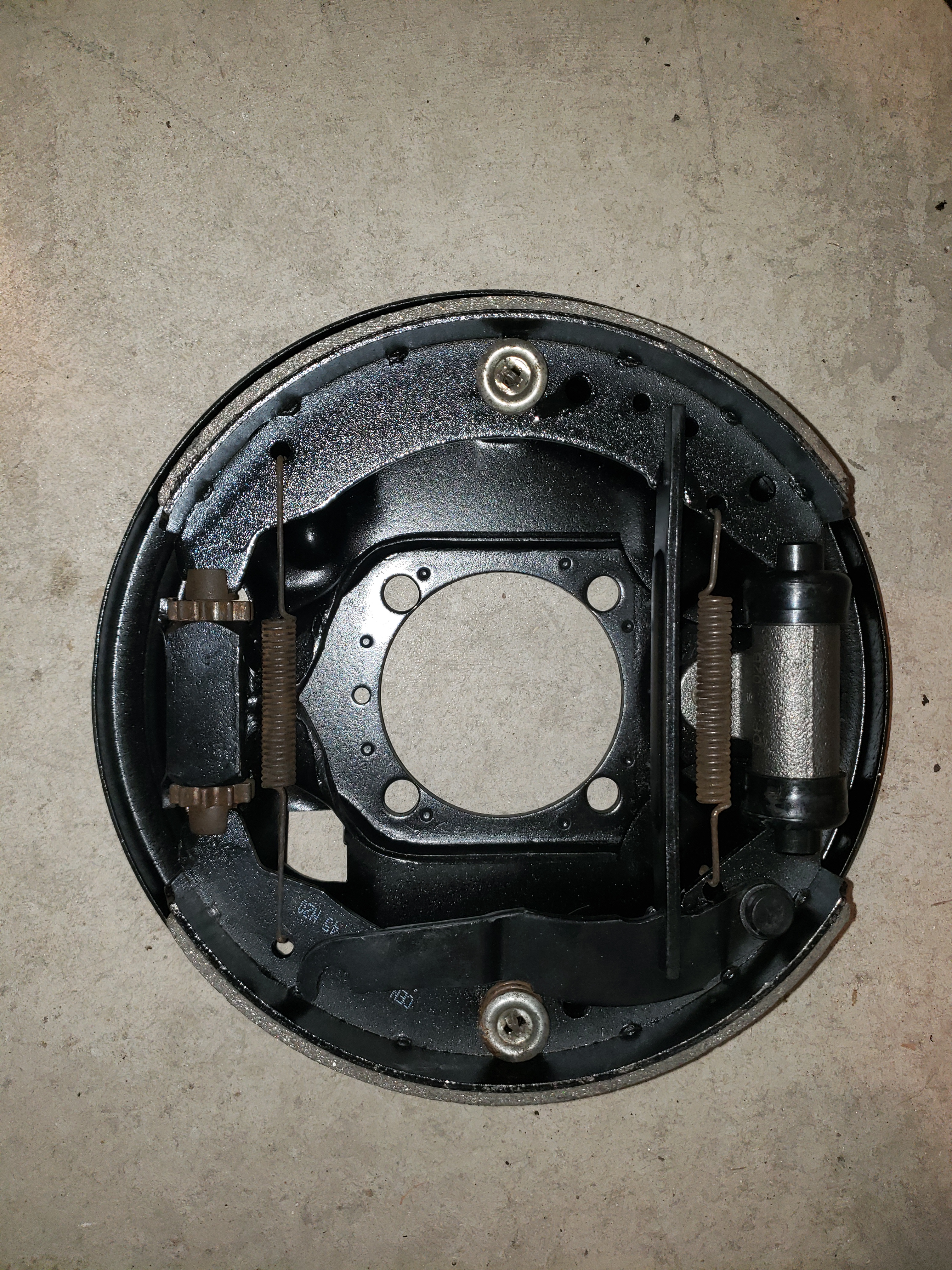

The backing plates and bearing caps were blasted. Everything was painted, new shoes, wheel cylinders, axle boots, and wheel bearing axle seals were installed.

To convert the transmission from a 6 volt to 12 volt flywheel the bell housing needs to be ground for clearance at the four points where the engine studs and bolts go through, and next to the starter bushing. I use a spare flywheel to check clearance as I grind to check the fit. The starter bushing was replaced with a 6 volt to 12 volt conversion bushing as well to accept the smaller 12 volt starter shaft.

Everything back in the car and now that the transmission is taken care of, it’s ready for some bodywork before that engine goes back in.

Copyright 2022