This car is a real complete vehicle that has been sitting for awhile. There is a nice smell of vintage upholstery in it as you open the doors and enjoy all of the original features still intact in this mostly original car. There is some signs of rust to repair in the rear wheel well and body mount area.

I received the car complete less the engine and the decklid had come off the car. There were four huge boxes with new fender to replace the damaged ones. It looks like the rear drum came off the car and took out the driver’s rear fender.

Everything is pretty much intact, appears to be functional, and is in great preserved condition. It was stored away for awhile to keep things this decent. The seat have been upholstered recently.

The repairs were done to the car some time ago with the damage to the A-pillar. The blue was painted quite awhile after, and was a quick paint job. The car was stored with the blue paint job for while to preserve it’s condition.

There was some type of sealant added to the edge of the passenger side the hide the rust when it was painted blue, but the driver’s side is solid. The heat channel is really rusty along the passenger side and the front quarter was replaced after a previous accident at some point.

There is quite a bit of filler in the quarter panel and signs of brazing the panel back on to the car.

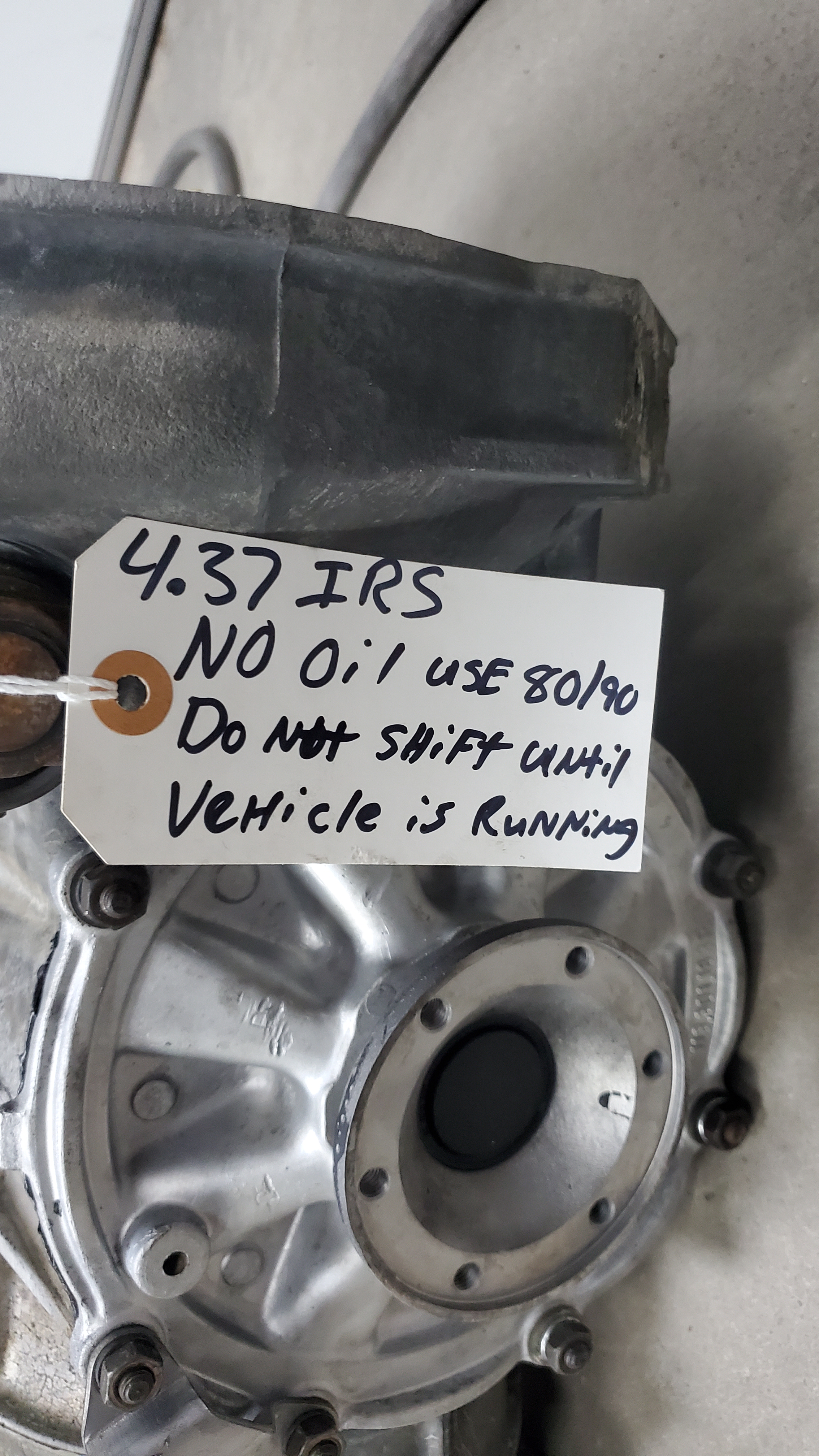

The vehicle is getting a mild lift and conversion to Independent Rear Suspension. I picked up some IRS arm jigs, a rebuilt transmission came from Painter’s Grinding, and a used IRS section to do the conversion.

The transmission was set up for a little larger tires and left with Type I flanges as this is being built as a driver and shouldn’t see hard off-road use.

With all the corners welded up for fenders to be fit back to the body, I lift the shell to take care of the pan half that is rusted out and the heat channel on the passenger side.

It used IRS was taken apart, parts cleaned, blasted, painted, with new bearings, and seals. I cut the center section out of the heat channel (once the body is braced), and work the pieces out of the front and back after that.

The pan half was cut out, and then I come back and remove the lip that is welded to the chassis after. Once everything is ground down along the lip, punch the holes around the pan half, grind down around each hole, and fit the half to the body. Once the body lines up the pan half, I tack it in place, lift the shell, and weld the half.

The throttle arm was bent pretty good, and there wouldn’t be full throttle with this twisted like that. The pedal was disassembled, straightened, cleaned, blasted, painted, reassembled with a new clutch hook, checked tolerances and range of motion, and cables replaced. The front quarter was previously repaired, but they decided to use silicone caulk to attach all the inner panels! No welds at all on the inside!

I went around the interior panels with screws to pull everything tight, and welded the seams together to give the front end some structural integrity. The swing axle was pulled out, and the torsion area cleaned.

The IRS arm jigs should be bolted in place with a block of wood between the jig and the end of the torsion tube. This will space the pocket on the outside of the frame horn to be able to mark where the pocket will need to be cut into the frame horn on each side. I bent the lower corner of the pockets back towards the frame horns on both sides to minimize the gap from the angle of the pocket as it goes in the frame horn.

The spring plates were notched at the stop on both sides 1/4″ to raise the angle of the arms. The final ride height will have to be set with the full weight of the car once fully assembled. This is raised in the rear and stock in the front. It’s a little nose down right now, but will be a little rear down once finished. The Thing arms and spindles will raise the front about 3″.

The shell is lifted again to start working on the rear body mounts, finish any welds needed, and I will finish up the rear end with everything out of the way. The pan has been cleaned up, painted, and is ready for axles and front end parts.

Copyright 2022-25