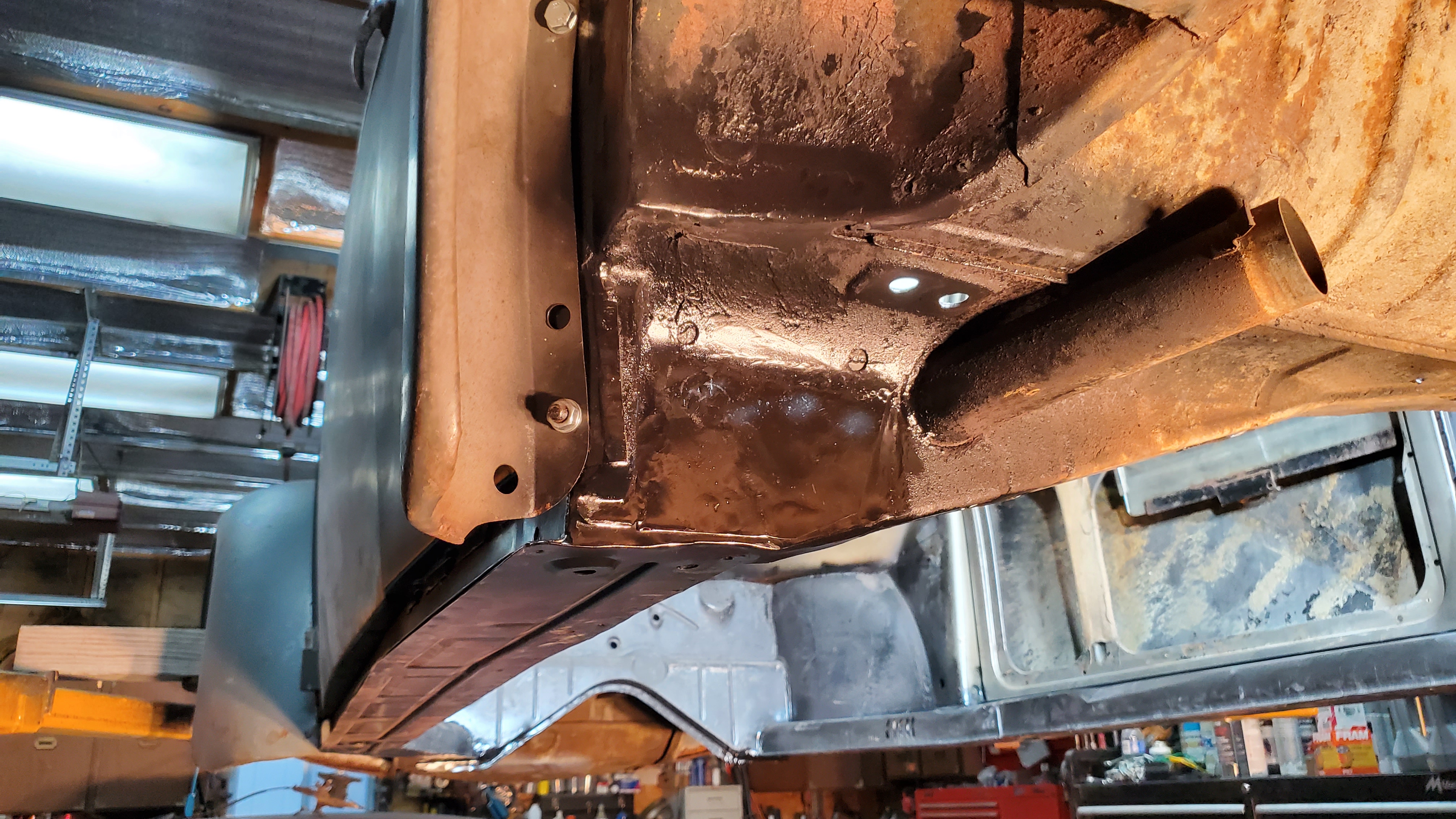

The chassis was thoroughly cleaned, degreased, and pressure washed multiple times to remove the buildup.

At some point, someone had a hard time with the shift coupler and severely damaged the surrounding metal. Everything was twisted and bent in an attempt to make space. Although a few lines couldn’t be straightened from the outside, the area now looks much better, and the cover will fit over the top without bulging.

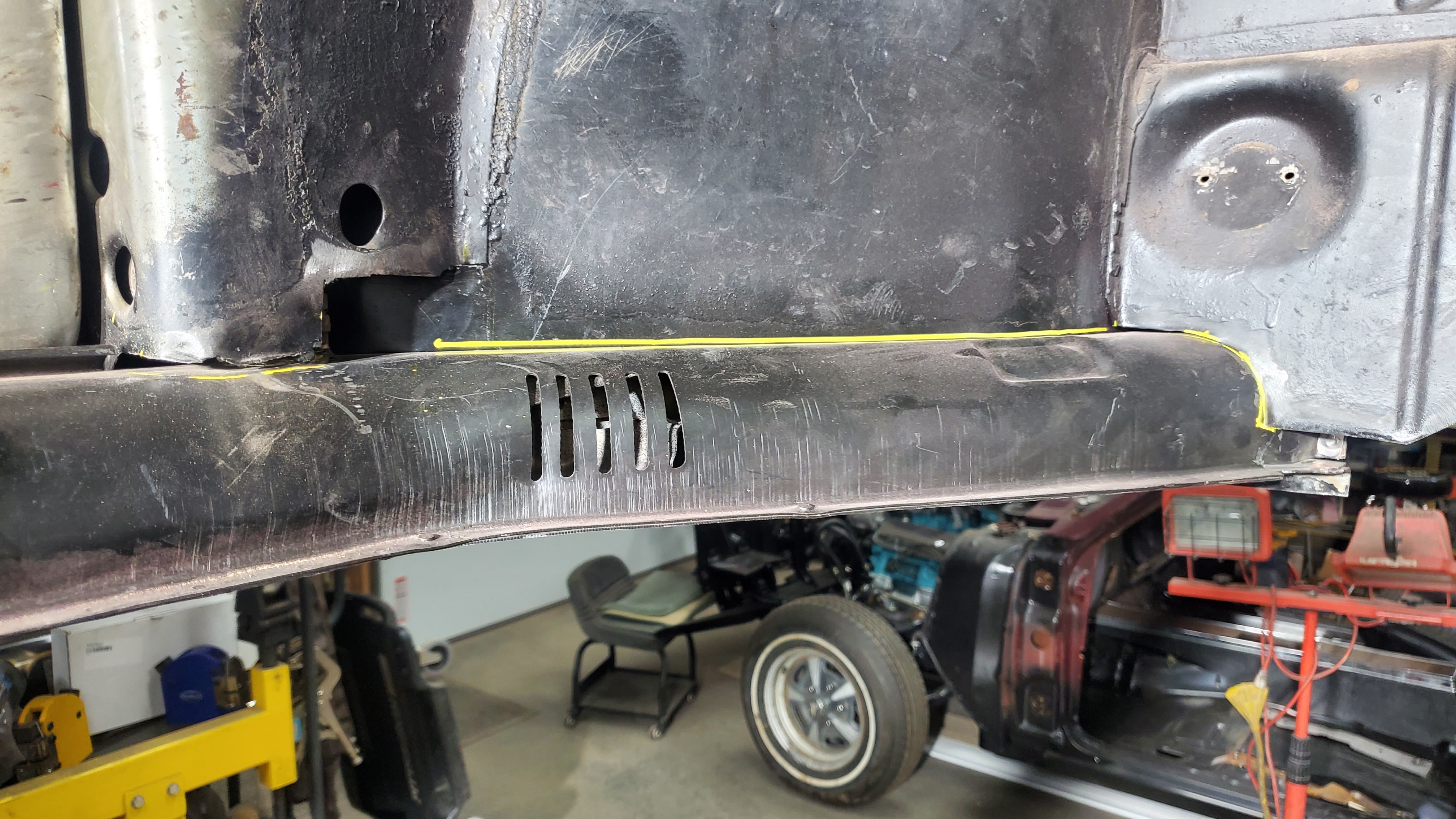

The heat channels were marked and screwed in place to be able to fit the pieces for assembly of the front wall and rear corners.

In the early cars, steel tubes were tack welded in place to connect the heat tubes to the windshield corner defrost ducts. These tubes were welded onto the channels, pressed into place, aligned with the marks, and screwed back in position.

The back of the channels have been welded in place, and the corners will require some work to connect. The corners consist of a couple of layers, with the inner panels repaired and painted before the outer panels are welded over them. All interior surfaces and the backs of the repair panels are cleaned and painted before welding.

All the pieces for the driver’s side lower a-pillar, front channel pocket, and front wall.

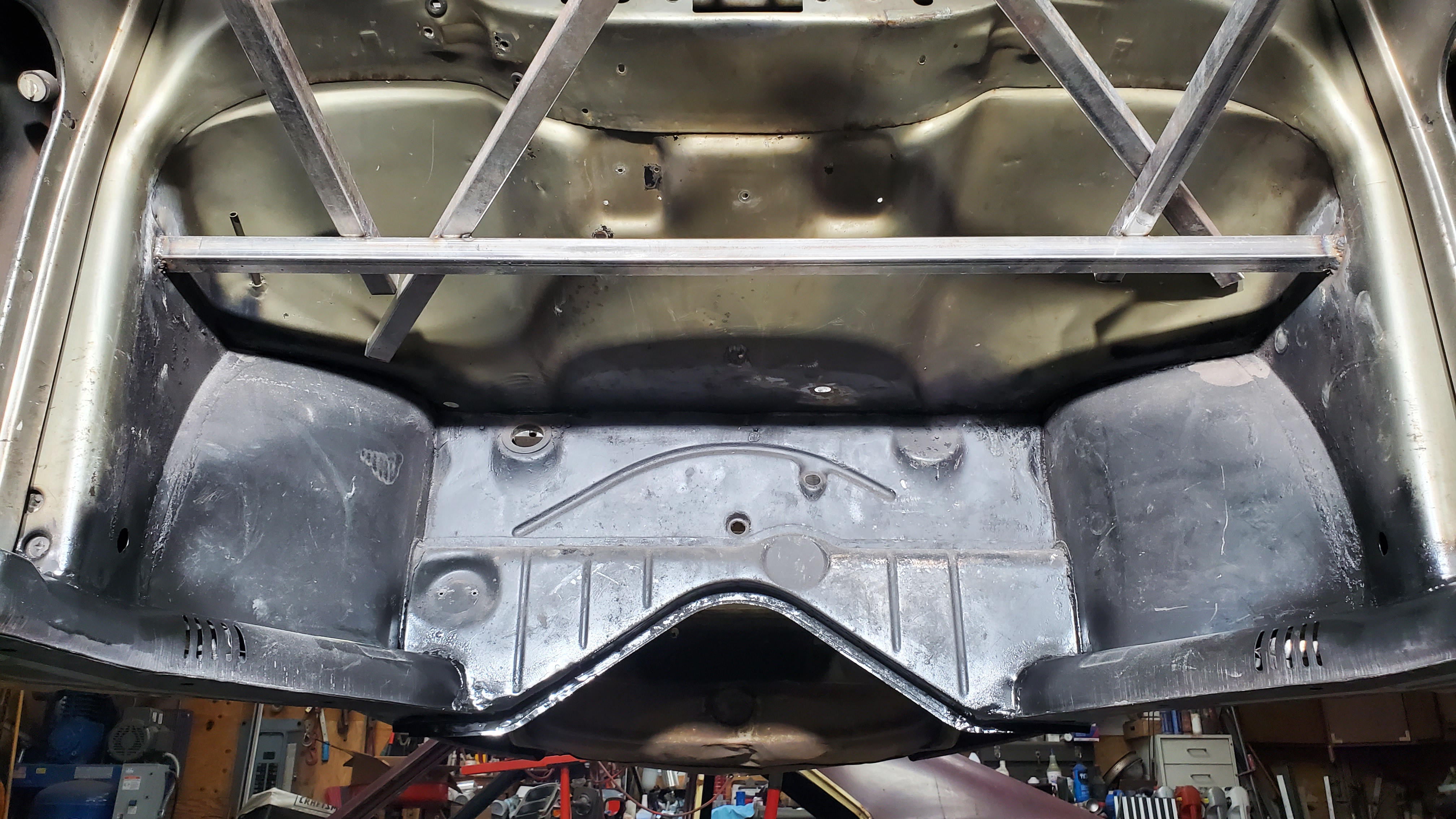

The heat channels, lower a-pillars, front heat channel pockets, front firewall, and both wheel wells welded in place.

The rear corners were in need of a couple layers of repair, and the outer layer was plug welded to the inner layer of the hear channel.

The passenger side rear corner was about the same as the driver’s side. There were a couple of layer fabricated to repair the rust damage, and the bottom of the channel was welded to the body.

The fender are mounted up and the bottom of the car has been repaired.

The body was lowered back on to the pan with the hoist, and the last part will be to finish the pan welds, add a pan seal, seam seal everything, and bolt things back together.

Copyright 2022-24